Our Products

Wood Coatings

Protect, preserve and beautify wood with the right wood coating

From walls to floor, wood has been a part of homes from times immemorial. This versatile and durable material is truly perpetual in its ability to adorn the spaces and fit perfectly into your interiors. With a wide range of substrates (hardwood, softwood, MDF, aged wood, or green wood) and applications (exterior, interior, furniture, building, residential, industrial), wood coating promises a vast industry with a plethora of products.

Colour Coats Wood Coatings enhance the natural wood coloration while protecting it from abrasion, chemicals, moisture, UV radiation, weathering, and attack from microbes such as fungi. Our wood coatings also assure remarkable resistance to regular foot traffic, giving a rich and new look to your floor and furniture.

Types of wood coatings

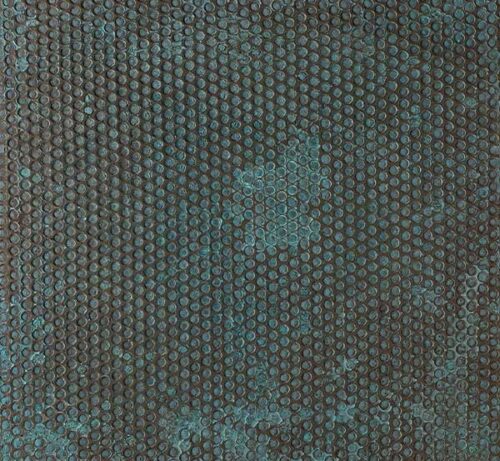

Wood finishes have qualities which work best when paired with the right application. Pigmented, Special Effects, Metal Coatings, Clear Coatings, Stains, and other such coatings help create the ideal finish. Which wood coating fits your needs depends on the type of wood and the end use of the substrate.

Featured Products

New Arrivals in Wood Coatings

- Metal Coatings

- Metal Coatings

- Metal Coatings

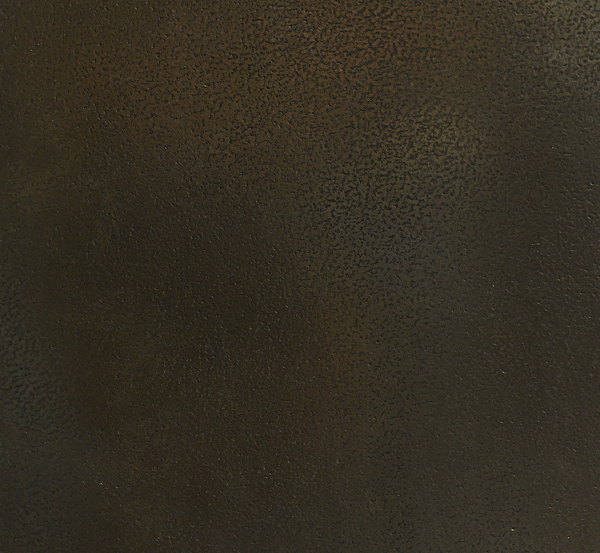

- Satin Metal